MIG Vs. TIG Welding? Expert Comparison & Pro Tips Revealed

Updated: 22 Nov 2023

207

MIG and TIG welding are often confused due to their similar names, but they are two different welding methods with unique applications. Although both used the same arc and shielding gas, the key disparity lies in the choice of the electrode.

There are some similarities and dissimilarities in both mig versus tig welding. They share an electrode where the MIG welding technique has a Consumable soiled wire while TIG has a tungsten non-consumable electrode.

Understanding MIG and TIG welding is essential for anyone who is seeking to master the craft of welding. By grasping its fundamentals and recognizing its strengths and weaknesses, welders can decide which best suits their projects.

After digging and searching the topic for quite a while, we came to a detailed guide about mig vs. tig welding strength, so let’s get to it without wasting any time.

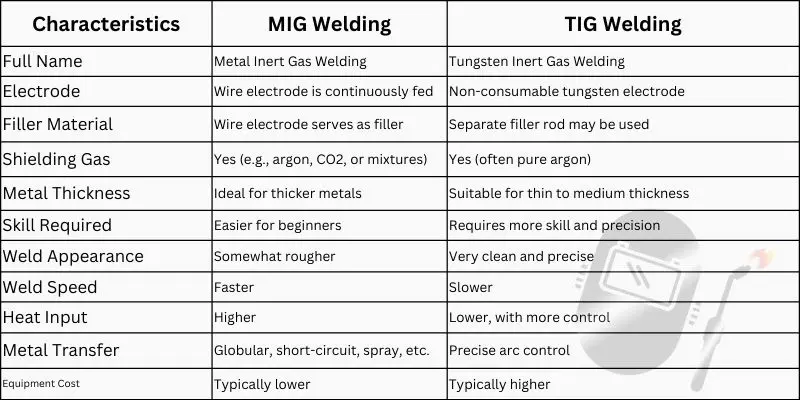

Quick Comparison of MIG Vs. TIG Welding

© weldingvilla.com – Image usage rights

MIG Vs. TIG Welding:

MIG welding and TIG welding are considered the two prominent methods in the world of welding. To most people, it seems similar, but it’s not. These similar techniques, both harnessing the power of an electric arc with protective gasses, weld anything you want.

For complete differentiation, let’s move to the article, but before that, let’s know what these weldings are.

What is MIG Welding?

MIG welding is also known as Gas Metal Arc welding, short for GMAW. In MIG welding, they used consumable wired electrodes for creating and farming an electric arc with a workpiece for melting material and wire to create welding for fixing or creations.

What is TIG Welding:

TIG welding is also known as Gas Tungsten Arc Welding in short (GTAW). This process of welding employs a non-consumable tungsten electrode to create its weld. This process offers precision, especially welding with thin materials.

MIG and TIG, How they Work:

How Does MIG Welding Work:

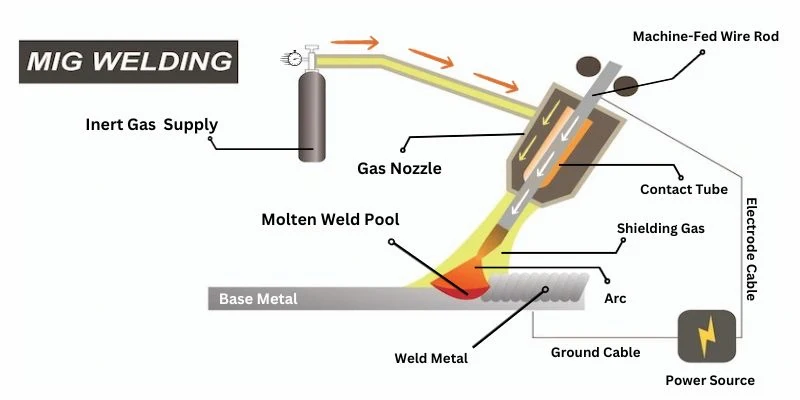

Source: https://weldguru.com/mig-welding/

The process that the mig weld uses is an automatic or semi-automatic arc for its welding. Its welding method involves a shielding gas with an electrode and a metal. There is also a torch, which is why it is called a welding gun, which feeds gas to its welding.

In this case, the weld filler is its electrode, which plays a central role in welding. It comes in various types and sizes, which usually depend upon which quality and type of material you are using, such as the material (metal), its width, and the area you are sewing with the weld.

The welding process of MIG welding involves the feeding of an electrode continuously from a spool through a welding gun. There are also shielding gasses that are usually made from mixing carbon dioxide and argon, which aims to protect and shield the whole process from atmospheric contaminants.

How Does TIG Welding Work:

Source: https://weldguru.com/mig-welding/

The TIG is known as Tungsten inert Gas because it uses tungsten as its primary material. This process uses arc welding as MIG welding but with a key difference. Instead of using consumables, it uses non-consumable tungsten electrodes through your hand instead of welding a gun.

The TIG welding process is the same as MIG welding, but you must manually feed the filler material whenever necessary. It also used shielding gas to prevent the weld from contamination, but it uses pure argon instead of a mixture of argon and carbon dioxide. The size and composition of TIG filler also depend upon its use, just like its MIG welding.

The Difference between MIG and TIG Welding:

Welding Strength:

Both welds produce the same level of welding strength, making them durable and strong for any work, but Tig weld is a bit strong due to its narrow focus on patron weld. The Tig weld gets a point in welding strength due to its better penetration of any metal.

Another thing that comes to mind is how clean it can get the weld, and that’s why TIG weld gets a point because of its clean weld compared to mig weld. It doesn’t mean that the mig weld is not strong; it also creates a strong weld as TIG welding if you position the torch with proper speed.

Speed of Welding:

The MIG welds win in this category because the mig welder provides better speed than TIG welding. The reason is simple: Mig welding provides the rod automatically with speed, while in TIG welding, you have to fill the rod with another hand, which can’t match the speed of the Mig welder.

Other than that, feeding the electrode or filler material to the MIG welder is easier than the TIG welding. That’s also the reason people like MIG Weld and then TIG Weld.

Welding Shielding Gas:

A shielding welding gas is very important in both weldings because it protects your welding puddle from reacting with other natural gasses, which can mix up your whole weld. Both of the processes use shielding gasses, but they are different from one another.

The Shielding gas used in MIG welding is a mixture of Carbon dioxide and Argon in the ratio of (Co2 = 25%, Ag = 75%). The gas prevents the weld from contamination and stabilizes the arc for penetrations.

On the other hand, TIG weld gas uses Pure Argon gas because carbon dioxide is too sensitive from its electrodes. The TIG welding used tungsten as its highly reactive electrode, so they used Argon, a nonreactive gas, for a safe process. But sometimes, they mix its shielding gas with nitrogen, hydrogen, and helium for special welding.

Difficulty to Learn:

If you are a beginner making your way into welding or end up there without having to choose, then MIG welding is just for you because it is easy, and you can pick it up just fine. Unlike TIG welding, there is no pedal to work with, and a machine does all the work; you just have to point it.

Another thing that makes it easy is its thick welding, which is easy to do, and all you have to do is learn how to hold an arc gun and pull the trigger. That’s also why people called it a “Hot glue Gun.”

On the other hand, we have TIG welding, which is a bit tricky and needs complete focus because you have to hold the Torch, and, on the other hand, you have to feed the filler rod. Just note that you must also control the amperage during your welding process by foot pedals. All of these require a fully concentrated mind, which is challenging to learn.

TIG welding also requires proper cleaning of the spot that you want to weld. TIG welding makes some quality solid beads only when you have done it correctly; otherwise, you miss it.

People who want to get into the welding business start with MIG welding because it is easier and cheaper than TIG welding.

Cost Comparison:

MIG welding is cheap and costs less than TIG welding because the speed of MIG welding is fast, which makes the cost of bead lower per foot. The process is easy and doesn’t require more effort, so its welder also charges less money.

On the other hand, the TIG welding is slow, which makes the cost of beads per foot expensive. It is a very complicated process that requires a trained welder, which also adds to its total cost.

At the end of the day, if you have the budget, you can go with TIG welding, but if you are low on pockets, come straight to TIG welding.

Applications of Both MIG Vs. TIG Welding

MIG Welding Applications:

MIG welding has a bunch of Applications and advantages. Some of its best Applications are given Below.

- Thicker Weld: The MIG welding is an excellent choice when you need and require thicker weld because it has thick material, which is also on automatic feed that can provide as long as you need.

- Continue Process: In many situations, the welding process should be continued, and that can only be better handled by MIG welding because it has continuous wire feeding, while in TIG welding, you have to stop the whole process to change the wire. There is a low chance of causing weld defects.

- Weld in Difficult Positions: As you know, MIG weld can be handled with one hand since then it is considered easy to weld in Difficult positions.

- Production Rate: The speed of creating beads per hour of MIG welding is higher than TIG welding. So whenever you need High speed of productivity, then MIG welding is the choice.

- Easy Achievable: As discussed above, MIG welding is easy to learn, and anyone can do and understand it. There is no complex learning curve in this process, and anyone can know it; with TIG welding, you must be certified.

TIG Welding Application:

Thin Material Welding:

Suppose you are welding some small, thinner materials. In that case, I recommend you choose TIG welding because it’s very effective against thin materials and can also be very precise compared to MIG welding.

Certified Welders:

As you know, TIG welding is hard to learn, but it also has a bright side, meaning whoever learns it will be a certified, experienced welder. Those skilled welders have less chance of making mistakes than MIG welders. That’s why there is a clear difference between mig and tig welders.

Precision Welding:

TIG welding can be done without proper position, which means that you have to position it properly, but when it’s in position, it has some of the best precision for welding, even better than MIG Welding.

Detailed Work:

The TIG welding is suitable for areas that need detailed work, like art pieces or restoration. Heat control is significant in detailed results by preventing further damage to the object.

Advantages and Disadvantages:

Just like everything, MIG to TIG welding has its Advantages and disadvantages. Both of their advantages and disadvantages are given below.

| Advantages of MIG Welding: |

|---|

|

| Disadvantages of MIG Welding: |

|---|

|

| Advantages of TIG Welding: |

|---|

|

| Disadvantage of TIG welding: |

|---|

|

Safety Consideration for MIG and TIG Welding:

If we can agree on something familiar in both of these weldings, it is its safety rules and regulations. There are some safety rules that you should follow no matter what type of welding you are using. Some of those rules are given below.

- Protective Gear: If you use a mig and tig welding machine, you should use the welding protective gear to protect yourself. The protective equipment includes head safety, including a helmet, gloves, apron, and special glasses. Remember: If you are not that expert as a professional or have no certification in welding, then be careful while using any welding machine; otherwise, you could hurt yourself.

- Ventilation: TIG and MIG welding create different fumes while welding, especially in a closed area or room. Sometimes, that fume can be dangerous to breathe in, so it’s essential to adequate proper ventilation.

- Electric Safety: Whenever you are in welding or in a place where electric wire is lying around, please be careful with those wires. Because it is dangerous and you could electrocute yourself.

FAQs:

What are MIG and TIG Used For?

MIG and TIG welds are used in almost all construction companies doing a lot of work. It is used for any metal, along with thermoplastics.

Is a MIG or TIG Welder better for Beginners?

When it comes to beginners, MIG welding is considerably easy to learn. The Mig welding is easy to do and learn because it has an automatic feeding filler for which you have to hold your Gun.

What is TIG Welding Mainly Used for?

Tig welding has a lot of applications and is mainly used for any sort of pipeline and pipe welding. Other than that, it is primarily used in aerospace, aviation, and sheet metal. It can be used with any metal.

What is the Main Difference Between MIG and Tig Welding?

There are some main differences between TIG and MIG welding. MIG welding uses an automatic feeder; you must provide it by hand in TIG. MIG welding, its shielding gas, is a mixture of carbon dioxide and Argon, while TIG welding is based on pure Argon.

What is the Strongest type of Welding?

Both Mig and Tig are considered strong welds, but TIG is often considered the strongest among them. It is because it produces extreme heat, and in that heat, it welds, which is very strong. Due to its slow cooling rate, it becomes solid and durable.

Conclusion:

Both MIG and TIG welding are better in their own way. If someone says one is better than another, it must depend on variables such as materials, situations, etc.

MIG welding offers a low cost of welding with different materials and has high production value, which is good, but when we need accuracy, TIG welding is the go-to welding. It’s expensive but worth it for thinner materials and detailed work.

Both are good and bad; choosing which is suitable depends on your needs and priorities.

Please Write Your Comments