Scratch Start Tig Vs. Lift Arc – Applications & Equipment Requirements

Updated: 21 Feb 2024

66

The pivotal decision between the scratch start and lift arc is critical, and most tungsten arc welders would know the difficulty because choosing a scratch start or lift arc is a prominent choice.

The process of scratch start tig welding is very simple. The process involves initiating the arc by striking or scratching the electrode to the workpiece, creating a spark, and forming the arc. Meanwhile, the difference in the lift arc process is that instead of touching, you have to take the electrode close to the workpiece, and it will start an arc.

Choosing between these two is crucial because it will affect your overall welding process. It will affect the overall quality of welds and prioritize the whole process into simple or complex. We detail its different characteristics, so let’s get to it.

What is Scratch Start Tig Welding:

The scratch start is one of the easy and straightforward processes of TIG welding torch start or ignition. This is also a cost-effective and cheap way to start your TIG welding arc. It doesn’t use high frequency or any other advanced methods to start its process; instead, it uses a very simple yet effective process.

The scratch start TIG is one of the easiest methods and makes contact with the tungsten electrode into contact with the workpiece, which then creates an arc. You can also slide the electrode on the surface, creating an arc that starts your Tig welding process.

This method is considered simple yet very versatile and uses almost every other material and different applications, which include aluminum, exotic alloys, and stainless steel.

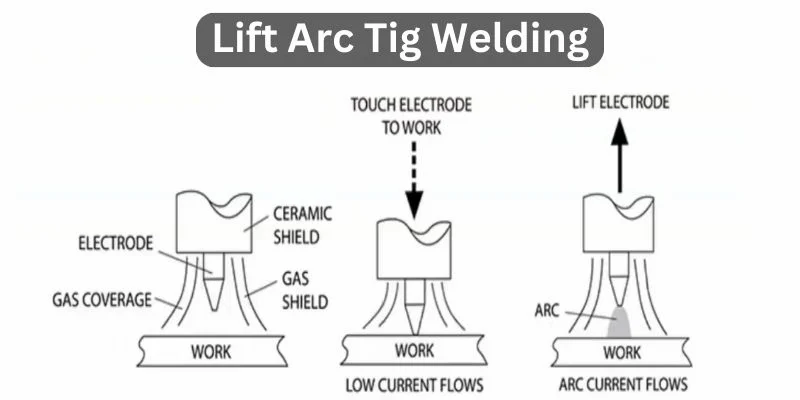

What is Lift Arc Tig Welding:

Lift arc is an advanced arc initiation process compared to other methods, especially the previous one. The technique is specially made to overcome the issues that happened with scratch start and make it even more sophisticated.

In these methods, you can start the initiates of the welding arc without the arc touching the electrode to the surface. You have to take it close to the surface metal but not touch it, and it will start an arc on which you can start your welding process.

This lift arc tig torch method is precise and gives you complete control over the arc, which also helps you minimize the risk of weld contamination. That’s why it gives you cleaner and proper welds and is preferred by almost every welder.

Scratch Start Tig Vs. Lift Arc Tig:

Tungsten Inert Gas (TIG) welding is one of the most used welding methods, with various initiation methods. Two methods are involved: scratch starts and a lift arc, which are common. Like everything else, these two methods have advantages and disadvantages, which let you decide which one to choose. Below, we define some of the basic differences between these two.

Arch Initiation Process:

The arc initiation process of both of these is different from one another. In the scratch start, you have to touch or move the tungsten electrode on its material surface, and it will create an arc, while in the lift arc process, you have to position it close to the surface, and it will create an arc without touching it. That’s also why it’s called a lift arc.

Tungsten Contamination:

This is prone to contamination because of its direct contact with the workpiece. The electrode in this process needs contact sharpening after some time because it gets rough after regular touching.

While in the process of lift Tig arc, it has less chance of getting contaminations because it avoids direct contact.

Control and Precision:

The precision in scratch start doesn’t have that much precision, and it also takes a couple of variations to start. It is also hard to control, which is why you must have the proper skills and precision for a precise start.

When we talk about the lift arc, it is precise and gives you a clean and controlled start every time. The control is controlled during every initiation process, and that’s why it reduces every possible chance of disruptions.

Ease of Use:

The scratch start is effortless to start and one of the simplest processes, which is also its key advantage. It has a minimum level of setup and is also cheap.

While the lift arc is very complex compared to the scratch start, it also offers proper and better support in terms of control and precision.

Skill Level:

The scratch start needs no skills, making it accessible for anyone, even beginners who have just started TIG welding.

The lift arc process is complex, and you can’t use it until you can precisely control its lifting.

Applications

The scratch start is one friendly way of ignition, and most people with simple hobbyists and repairs prefer this method of initiation. It doesn’t have high precision, but it is less critical.

The lift arc initiation method has the best precision, which makes it suitable for different expensive projects like exotic materials where cleanness and precision are required or any other critical applications you should consider.

Equipment Requirements:

The scratch start is minimalistic and doesn’t require any extra setup for the stuff of its process, while in lift arc, it may need additional components based on its capability.

Conclusion

Both scratch start and lift arc are good choices for tungsten welding, but the lift is considered better for TIG welding because it is precise and effective compared to the scratch start process, and most lift tig welders also suggest it. But if you do welding as a hobby, you can consider scratch start because it is cheap and easy, and you don’t want to be a skilled welder.

I hope you have understood the top, for more topics like these, please visit our main website.

Please Write Your Comments