What is Electric Welding? Types and Uses

Updated: 7 Feb 2024

77

Electric welding is considered a cornerstone of modern metalworking, which consists of a wide range of welding processes from arc welding to Mig welding.

Electric welding is a process in which electricity is used to heat two metals and fuse them into one metal. There are different types involved in this process as its subparts, so you can grasp your hand on any of these welding processes after understanding electric welding.

It is pivotal in our modern construction industry, from automotive to aerospace. Getting expertise in electric welding is enough for you if you want to join the world of metal and create durable and strong metal structures.

What is Electric Welding?

Electric welding is a welding technique that relies on the resistance heating principle. It occurs when electric current flows through a metal, which is, in this case, a metal workpiece, and then it faces resistance, which generates heat. This heat then helps to melt and fuse those metals by creating a joint as it cools down.

The concept of electric welding can be traced back to the 1800s, which brought advancement, and now, in the 20th century, it has become one of the main factors in contractions. Nowadays, almost every other construction company uses electric welding for its construction work.

How Does Electric Welding Work?

The process of electric welding is considered simple for most of you, but when we talk about depth, it’s considered to have a very detailed explanation. Below, we explain every step in detail, so let’s get to it.

Creation of Heat:

First, electric welding creates an arc between electrodes, usually in a rod and metal wire. Based on the welding machine, the arc could be mild or intense, reaching a specific temperature that melts and fuses the metal.

Power Source:

The power source is considered very important in every welding process, especially in electric welding. The welding source depends upon its voltage capacity, which is also considered essential. Different types of welding processes require different power sources, so check before you start it.

Electrodes:

In electric welding, the electrode is used to conduct electricity to the workspace of the welding machine. Most of the electrodes are consumable and consumed due to the melting process, while there are also non-consumable ones that remain intact during the process.

Formation of Arc:

As you take the electrode closer to the workpiece, prevent it from direct contact. When it gets close enough to the surface metal, the electrode gets or starts an electric arc that strikes the metal with extreme intensity with continuous electricity discharge.

Fusing and Melting:

That electric arc generates intense heat, which is the reason for the melting of the weld. The electrode melting on the metal creates a weld pool, which later gets cold and forms a weld. The melted weld was soft for some time but became hard and solid.

Shielding:

Some of the welding processes need shielding gas from contamination, while others don’t. That’s why some welding needs shielding to prevent the welding pool from getting confirmation to ensure clean, safe, and strong weld.

Electric Welding Types:

Electric welding contains different types of welding processes which have unique applications. Below, we explain some of them, so let’s hop in.

Arc Welding:

Arc welding is one of the best examples of electric welding because it creates an arc with the help of electricity. A tremendous amount of heat is generated in creating an arc, which melts the metals to form a proper weld.

The arc welding is further divided into multiple categories, that is, shielded metal arc welding and gas metal arc welding.

Resistance Welding:

Resistance welding is also considered a central part of electric welding because it uses resistance to join two metals. This type of welding has also been used in the industry for some time and was also found to be very useful.

Resistance welding is mainly used in most manufacturing industries, such as the automotive industry. These methods include seam welding and spot welding.

TIG Welding:

TIG welding is referred to as Tungsten welding, which is also produced with the help of an arc. Electric welding is considered one of the most precise welding techniques, and most industries that require precision use this welding technology.

The type of welding is mainly used in aerospace and artistic processes due to its efficiency and clean welding methodology.

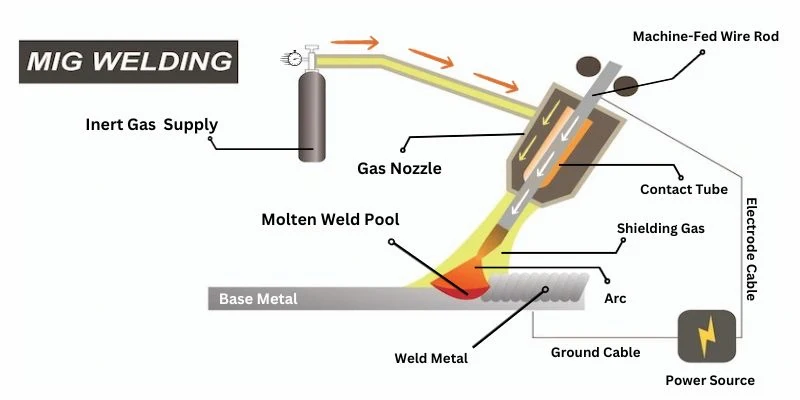

MIG Welding:

Source: https://weldguru.com/mig-welding/

MIG welding uses consumable wire for its welding process, which is utilized through its welding gun along with its shielding gas. This electric welding process is one of the fastest and easiest to learn, and even if you are a beginner, you can start with little experience.

This type of electric welding is extensively used in fabrication and construction.

Submerged Arc Welding:

Submerged arc welding is different from electric welding. In this process, an arc is created underneath the blacked flux, protecting the weld from any atmospheric contamination.

It is primarily used in heavy-duty applications requiring efficiency and durability.

| Advantages of Electric Welding: |

|---|

Following are the benefits of the electric welding process that make it popular in the welding industry.

|

Conclusion:

Electric welding is one of the construction pioneers because of its usage in most construction companies. It has a lot of sub-parts that serve its purpose in different infrastructures.

I hope you understand the topic, but if you have any questions, please consider asking in the comment section.

Please Write Your Comments