Parts of a Weld – A Deep Dive into Components and Structures

Updated: 15 Dec 2023

124

In order to improve our knowledge and gain expertise in welding, it is essential to get a deep understanding of parts of a weld. Every part has its role in combining two pieces of metal.

Some parts are involved in penetration, and some hold the surface. These weld parts are also involved in weld aesthetics and look beautiful after welding. If you want to get a deep understanding of every single part of a weld, then let’s go.

If you want to read about the different types of welding patterns, then click the linked text. Continue Reading…

Explaining the Parts or Components of the Weld:

Here are a few parts that will give you a deep understanding of a weld; let’s go deep into it.

1. Weld Face:

The weld face is the exposed surface created by the welding torch. Understanding the weld face is crucial for judging the quality of the weld and its appearance.

2. Weld Toe:

The weld toe is the interface between the weld face and the base metal. It is also the starting point of the weld and has a significant impact on joint strength.

3. Work Surface:

The work surface is the area where welding is performed. A clean and properly prepared work surface is vital for achieving high-quality welds.

4. Fusion Zone:

It is also known as filler penetration; the fusion zone represents the surface of the base metal that undergoes melting during welding.

5. Weld Root:

It is opposite the weld face; the weld root is where the weld interfaces with the base metal at the bottom of the joint. It is an important part where penetration and connection with base metal occur.

6. Root Penetration:

Root penetration refers to the depth of the weld into the base metal. It ensures the strength and durability of the joint.

7. Weld Leg (Weld Size):

The weld leg is the distance from the weld toe to the weld root. To achieve the desired size and strength of the weld, it is crucial to understand and control the weld leg.

8. Weld Reinforcement:

It is the height of the weld above the base metal surface. It ensures the weld’s structural integrity.

9. Fillet Weld Throat:

The fillet weld throat (Theoretical Throat) is a parameter that defines the perpendicular distance from the weld’s hypotenuse to the root. It is essential in determining the weld’s strength and load-carrying capacity.

Diagrams Illustrating Weld Parts:

There are two diagrams that provide visual clarity about the different components of a weld. Let’s explore graphs representing parts of a fillet weld and a groove weld.

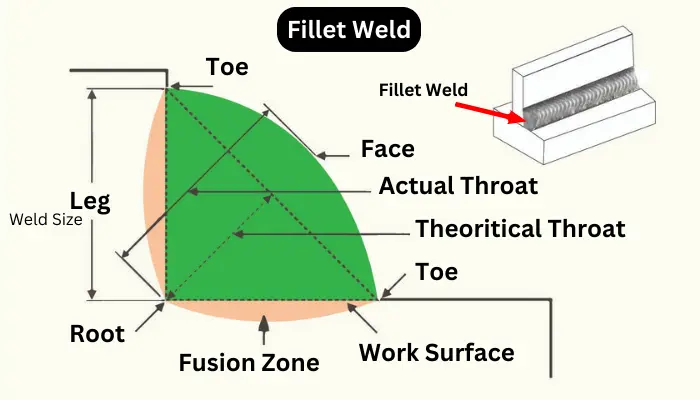

Parts of a Fillet Weld

A fillet weld is a weld that combines two pieces of materials (Metal) at the right angle (90-degree angle) in which the metal pieces are perpendicular to one another. The bead rests within the inner corner formed by the base metal.

© weldingvilla.com – Image usage rights

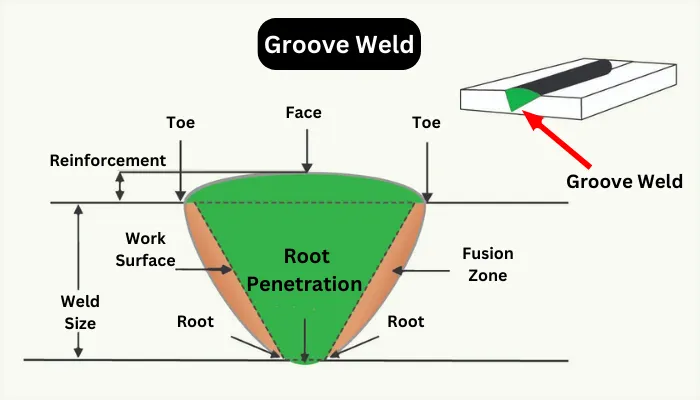

Parts of a Groove Weld

A groove weld is a weld between two workpieces in which one work surface makes an angle of 45°, and another makes 120°. In groove weld, the place of a beat is in the middle of these metal workpieces.

© weldingvilla.com – Image usage rights

What are the Sizes of the Weld?

There are three different sizes of a weld depending on the leg lengths and root penetration. These are given below;

1. Fillet Weld with Equal Leg Lengths:

The size of a fillet weld depends on the leg length; if the fillet weld has equal leg lengths, then the measure will be designated according to both sides of the workpiece (leg length).

2. Fillet Weld with Unequal Leg Lengths:

The size of the fillet weld with unequal leg length will be designated according to the large leg length.

3. Groove Weld Size:

The groove weld size depends on the root penetration and the depth of the weld surface. If the weld surface increases, the size will automatically increase and vice versa.

Frequently Asked Questions:

What is the purpose of the weld bead?

Weld bead is the filler material that fuses with the base metal to form a solid and durable joint.

How does the base metal contribute to the weld?

The base metal serves as the foundation for the weld, and it is joined and affected by the weld during the welding process.

Final Thoughts:

Understanding the anatomy of a weld is essential for welders and professionals in industries where welding is joint. Each component, from the weld face to the penetration root, plays a specific role in determining a weld’s strength, quality, and durability. These key concepts produce high-quality welds and contribute to the integrity of welded structures.

Now, you have a complete understanding of the weld parts. But you are still available to ask any question related to this topic. Our team will answer your query as fast as possible.

If this article is helpful for welders like me, then share it with your welding community. Your one share may solve someone’s understanding. Thank you for visiting and spending time with us. See you in the next article with Welding Villa.

Please Write Your Comments