Forehand and Backhand Welding Technique – Comprehensive Guide

Updated: 12 Jan 2024

91

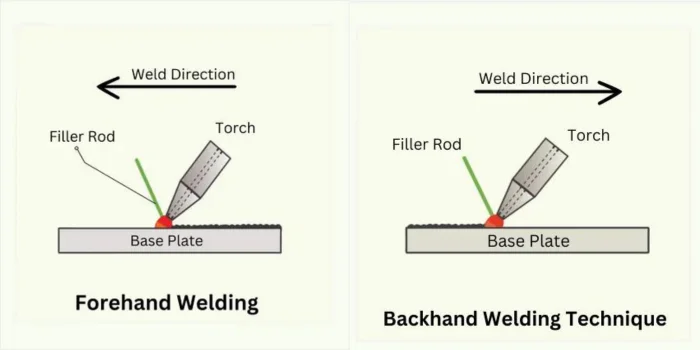

The forehand and backhand welding techniques are basic approaches in various welding processes to achieve specific weld characteristics. These techniques are essential in determining factors such as penetration depth, heat input, and overall weld quality.

Whether it is shielded metal arc welding (SMAW), gas metal arc welding (GMAW), or other welding processes, understanding the differences between forehand and backhand techniques is essential for welders who aim to master their welding skills.

In this exploration, we will learn these two welding methods, examining their applications, advantages, and considerations to comprehensively understand how they contribute to the art and science of welding.

Understanding Forehand Welding:

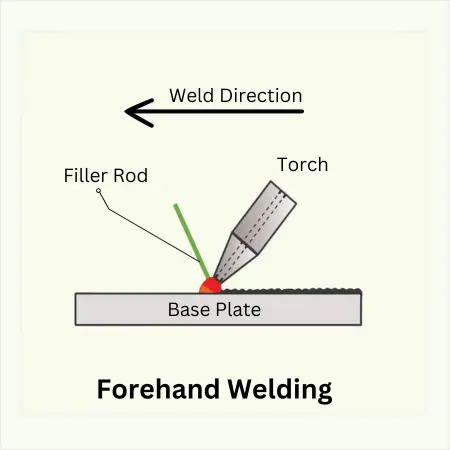

It is also known as “push welding” or “forward welding”. This technique involves moving the welding torch or electrode toward the weld. This technique is characterized by pushing the molten metal pool ahead of the arc, creating a more fluid and controlled weld.

© weldingvilla.com – Image usage rights

Key Steps for Forehand Welding:

- Joint Preparation: Begin by preparing the joint according to the welding specifications. Ensure proper cleaning and fit-up for a solid and clean weld.

- Electrode Angle: Maintain a slight lead with the electrode or welding torch, typically at an angle of 30 to 15 degrees in the direction of travel.

- Travel Speed: Control the travel speed to allow for proper deposition of the filler metal. Too fast can result in insufficient penetration, while too slow may lead to excessive heat input.

- Arc Length: Maintain a consistent arc length to prevent spatter and ensure proper fusion. Adjust the arc length based on the welding parameters and material thickness.

- Overlap Technique: Achieve good overlap between the weld passes to create a strong and continuous weld bead.

Applications of Forehand Welding:

Forehand welding is commonly used in various welding processes, including:

- Gas Metal Arc Welding (GMAW): Ideal for thin materials and out-of-position welding.

- Flux-Cored Arc Welding (FCAW): Effective for welding in windy or adverse conditions.

- Submerged Arc Welding (SAW): Suitable for high-deposition welding on thick materials.

| Advantages of Forehand Welding: |

|---|

|

| Challenges in Forehand Welding: |

|---|

Forehand welding may result in limited penetration in specific applications compared to the backhand technique, making it less suitable for thicker materials. |

Understanding Backhand Welding:

It is also known as “pull welding.” It involves moving the welding torch or electrode against the direction of the weld. This technique is characterized by dragging the molten metal pool behind the arc, allowing deeper penetration.

© weldingvilla.com – Image usage rights

Key Steps for Backhand Welding:

- Joint Preparation: Similar to forehand welding, ensure proper joint preparation for optimal weld quality.

- Electrode Angle: Maintain a slight drag or trailing angle, typically at an angle of 5 to 15 degrees opposite the travel direction.

- Travel Speed: Adjust the travel speed to control the heat input and penetration. Slower speeds may be required for thicker materials.

- Arc Length: Consistently maintain the appropriate arc length to ensure a stable arc and proper fusion.

- Stringer Bead Technique: Employ a stringer bead technique for single-pass welds, moving the electrode or torch in a straight line along the joint.

Applications of Backhand Welding:

- Shielded Metal Arc Welding (SMAW): Suitable for welding thick materials and achieving deep penetration.

- Gas Tungsten Arc Welding (GTAW): Precise control makes it ideal for welding thin materials and intricate joints.

- Submerged Arc Welding (SAW): Effective for high-deposition welding in the flat or horizontal position.

| Advantages of Backhand Welding: |

|---|

|

| Challenges in Backhand Welding: |

|---|

The molten metal pool is behind the arc, making it challenging for welders to monitor the weld pool and control the bead profile. |

Tips for Mastering Forehand and Backhand Welding:

Here are the four main tips for mastering FW and BW welding techniques.

1. Practice Regularly:

You can quickly improve these skills/techniques through regular practice. Dedicate time to practicing both forehand and backhand techniques.

2. Understand Materials:

Different materials have different requirements in techniques. Educate yourself about the materials you are welding and adjust your approach accordingly.

3. Maintain Consistency:

Consistency in travel speed, electrode angle, and arc length is essential for getting high-quality welds.

4. Safety First:

Always ensure safety by wearing high-quality personal protective equipment (PPE) and ensuring a well-ventilated workspace.

Topic Related FAQs:

Can both forehand and backhand techniques be used in the same welding project?

Yes, it depends on the project’s specific requirements; welders may use a combination of forehand and backhand techniques to get the desirable welding characteristics.

Do forehand and backhand techniques apply to all welding processes?

No, the application of these techniques varies in different welding processes. For instance, they are commonly associated with shielded metal arc welding (SMAW) but may be less relevant in other processes like gas tungsten arc welding (GTAW).

Final Thoughts:

Mastering forehand and backhand welding techniques is essential for any welder seeking to excel in their craft. Whether you are welding thin or thick materials, understanding when and how to apply these techniques will lead to strong, more reliable welds. Remember, practice, patience, and a commitment to safety are the keys to becoming a professional welder.

Now, you know how to apply these techniques, but if you need clarification, you can ask in the comment section. You can contact us on which topic (welding) you like to read a blog post. Our team will be there to help you with any issue in your welding journey. Thanks for visiting; take care of yourself and your fam

Please Write Your Comments